News

What the materials of the filter bag and how is the temperature?

filter bag Materials and Their Temperature Resistance

Filter bags are essential components in various industrial filtration processes, and the choice of material plays a crucial role in determining their performance and durability. Different materials offer varying levels of temperature resistance, chemical resistance, and mechanical strength. This article will discuss some common filter bag materials and their temperature resistance capabilities.

- PPS (Polyphenylene Sulfide) Filter Bags

- Temperature Resistance: PPS filter bags can withstand continuous operating temperatures of up to 190°C and short-term exposure to temperatures of up to 240°C.

- Chemical Resistance: PPS is known for its excellent resistance to acids, bases, and organic solvents, making it suitable for a wide range of industrial applications.

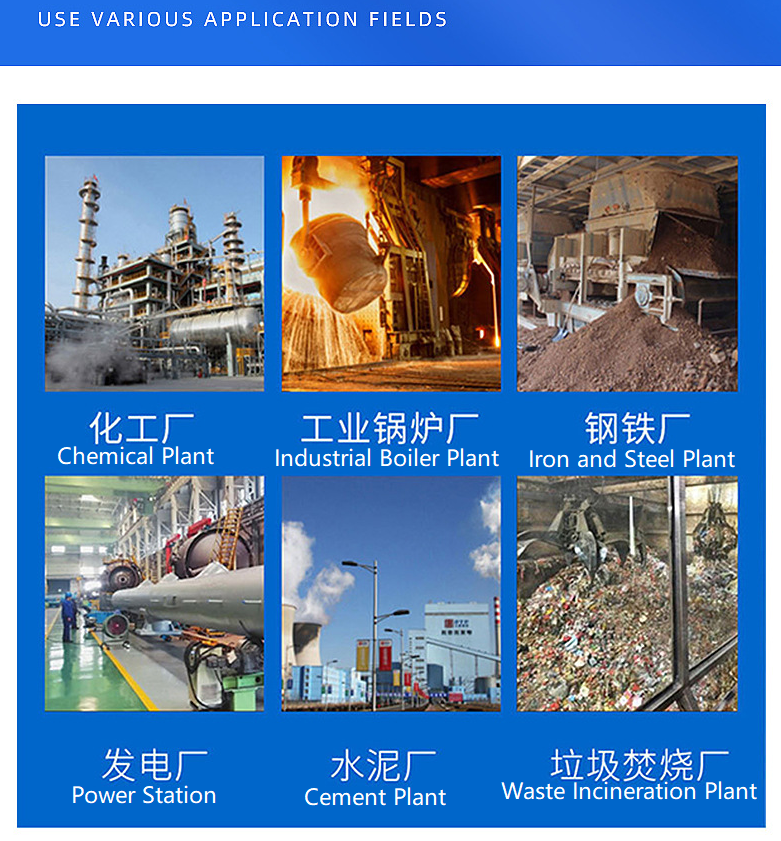

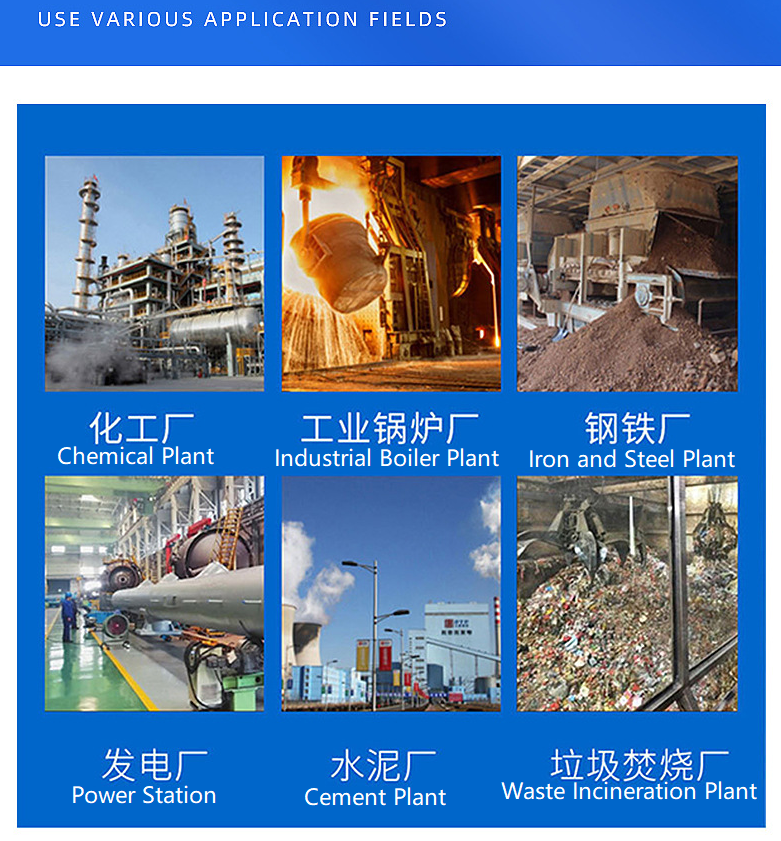

- Applications: Commonly used in power plants, cement plants, and chemical processing industries where high temperatures and corrosive gases are present.

- PTFE (Polytetrafluoroethylene) Filter Bags

- Temperature Resistance: PTFE filter bags can handle continuous operating temperatures of up to 260°C and short-term exposure to temperatures of up to 300°C.

- Chemical Resistance: PTFE is highly resistant to almost all chemicals, including strong acids and bases, and has excellent hydrolytic stability.

- Applications: Ideal for use in environments with extreme chemical corrosiveness, such as in the pharmaceutical, chemical, and waste incineration industries.

- P84 Filter Bags

- Temperature Resistance: P84 filter bags can withstand continuous operating temperatures of up to 230°C and short-term exposure to temperatures of up to 260°C.

- Chemical Resistance: P84 offers good resistance to acids and bases, but is not as resistant to hydrolysis as some other materials.

- Applications:Commonly used in applications such as coal-fired boilers, cement kilns, and waste incinerators that require efficient filtration and high temperature resistance.

- Meta-aramid (Nomex) Filter Bags

- Temperature Resistance: Meta-aramid filter bags can handle continuous operating temperatures of up to 204°C and short-term exposure to temperatures of up to 240°C.

- Chemical Resistance: Nomex has good resistance to alkaline conditions and moderate resistance to acids.

- Applications:

- Commonly used in asphalt mixing plants, industrial furnaces, and coal-fired boilers.

- Glass Fiber Filter Bags

- Temperature Resistance: Fiberglass filter bags can withstand continuous operating temperatures up to 260 ° C and short-term exposure temperatures up to 300 ° C.

- Chemical Resistance: Glass fiber has excellent chemical resistance and can resist corrosion from most acids (except hydrofluoric acid), but it will corrode in strong alkaline environments at room temperature and moderate alkaline environments at high temperatures.

- Applications: Suitable for applications that require high temperature resistance and good dimensional stability, such as coal-fired power boilers and waste incinerators.