Composition

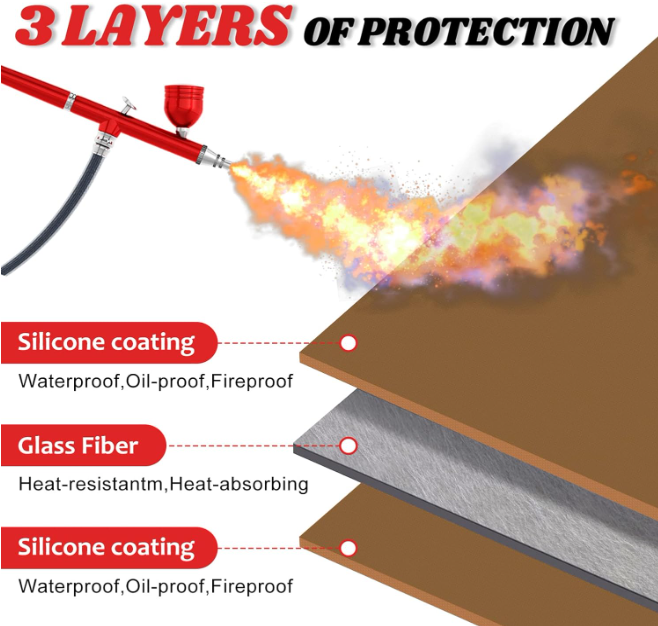

Under Grill Mat is primarily made of two key components: silicone rubber and fiberglass. Silicone rubber, a synthetic elastomer, is renowned for its excellent heat resistance, chemical stability, and flexibility. Fiberglass, on the other hand, is an inorganic non-metallic material composed of fine glass fibers, which imparts exceptional mechanical strength, electrical insulation, and thermal resistance to the composite.

Characteristics

- Heat Resistance: Silicone fiberglass pad can withstand high temperatures up to 1000°C, making it ideal for applications in extreme thermal environments.

- Chemical Resistance: It is resistant to a wide range of chemicals, including oils, fuels, and various solvents, ensuring long-term performance and durability.

- Electrical Insulation: The material offers excellent electrical insulation properties, making it suitable for use in electrical and electronic applications.

- Low Smoke and Toxicity: In the event of a fire, silicone fiberglass pad produces low smoke and minimal toxic fumes, enhancing safety.

- Flexibility and Durability: The combination of silicone rubber and fiberglass results in a material that is both flexible and durable, capable of withstanding mechanical stress and vibration.

Applications

- Automotive Industry: 3 Layers Fire Pit Mat is commonly used in exhaust systems, gaskets, and seals due to its heat and chemical resistance.

- Aerospace: The material's lightweight, heat resistance, and electrical insulation properties make it ideal for use in aerospace applications, such as engine components and thermal barriers.

- Electrical and Electronic: Silicone fiberglass pad is used in electrical insulation, transformer cores, and as a protective layer in circuit boards.

- Industrial Equipment: The material is employed in high-temperature seals, gaskets, and insulation in industrial equipment, including boilers, furnaces, and ovens.

- Food Processing: Due to its FDA-compliant and non-toxic properties, silicone fiberglass pad is used in food processing equipment as seals and gaskets.

Advantages over Traditional Materials

- Longer Service Life: Compared to traditional materials like rubber and cloth, silicone fiberglass pad offers a significantly longer service life due to its superior heat and chemical resistance.

- Reduced Maintenance: Its durability and resistance to degradation reduce the need for frequent maintenance and replacement.

- Enhanced Performance: The combination of silicone rubber and fiberglass results in a material with superior performance in terms of heat resistance, electrical insulation, and mechanical strength.

- Customizability: Silicone fiberglass pad can be customized in terms of thickness, size, and shape to meet specific application requirements.

- Cost-Effective: Despite its advanced properties, silicone fiberglass pad is relatively cost-effective, making it a viable alternative to more expensive materials.

In conclusion, silicone fiberglass pad is a versatile and high-performance material that offers a wide range of benefits in various industries. Its unique combination of properties makes it an ideal choice for applications that require heat resistance, chemical stability, electrical insulation, and durability.